LONGi has established the Quality Management Committee and set up a continuous improvement organization covering the entire group in 2023. We issued four documents on the procedure and system of continuous quality improvement to enhance the capability of all employees to identify and address quality issues and specify quality management responsibilities at all levels. Through a comprehensive and science-based quality management system, we strive to ensure effective implementation of quality management to facilitate the implementation of the company's business strategies.

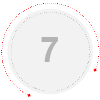

Comprehensive Management of Lifecycle Quality

LONGi is committed to achieving high quality in line with high standards and integrates LONGi’s “Product Lifecycle Quality Standard” into every stage of product design, production, and application to ensure excellence in quality standards throughout the entire product lifecycle.

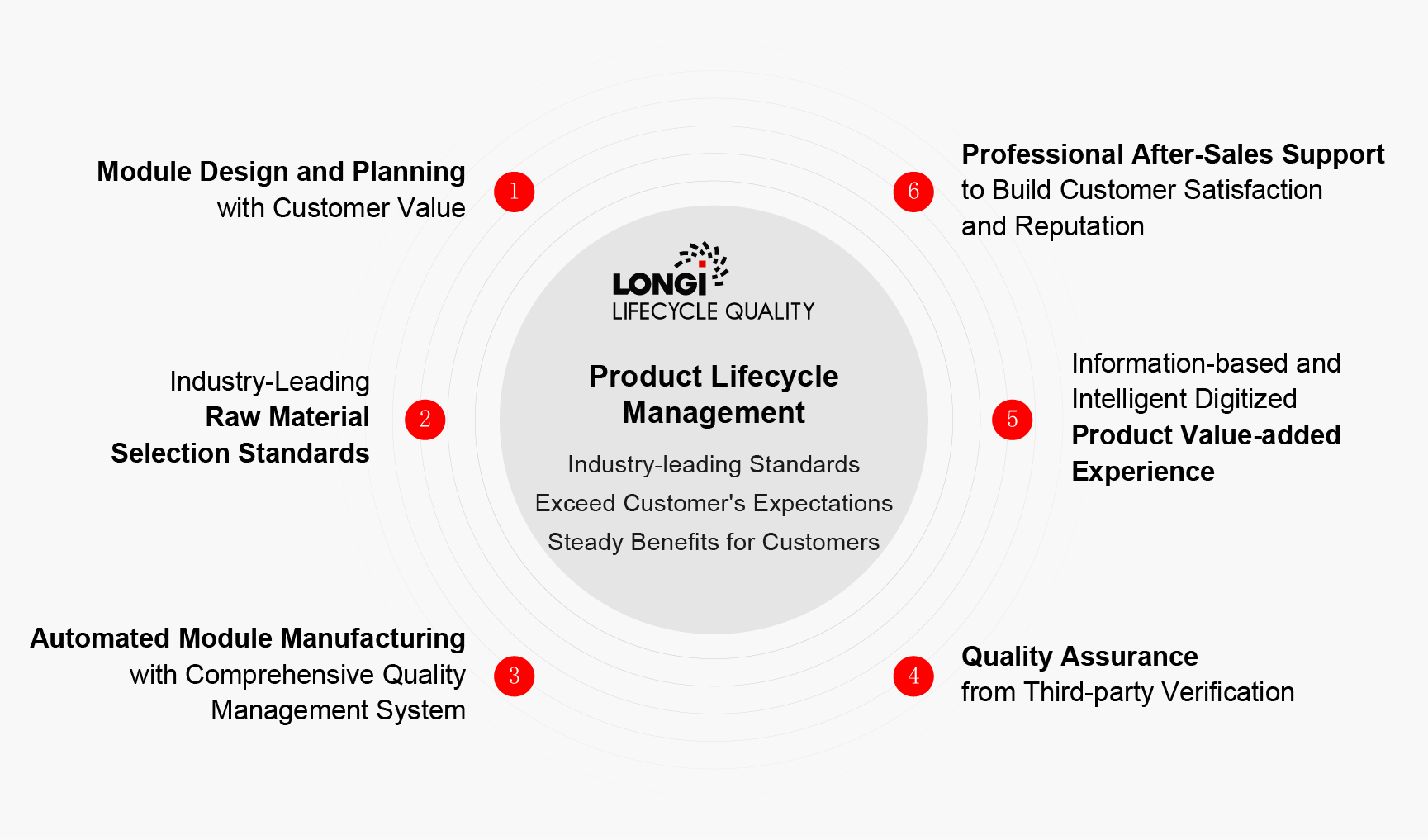

In 2023, we focused on optimizing the quality management process for new product development. With module products as the pilot, we standardized quality strategy, quality planning, quality data management, quality risk, and issue management for new products. By clarifying quality objectives from the project initiation stage and breaking down these objectives into specific requirements and standards for each stage, we achieved effective and stringent monitoring of key processes, which significantly enhanced the quality and efficiency of new product development.

Quality System Management

| Quality Information System

Longi regards Quality Big Data as core driving force to promoting the Total Quality Management Digitalization strategy. We have built an ‘1+7+1’ Quality Informatization management system, focusing on quality data throughout product full life cycle to achieve collection, management and analysis of quality data in all aspects as while as establishing an on-line traceability system to ensure stability and traceability of product quality. In 2023, by operating under‘1+7+1’Quality Informatization management system , we have achieved 10% man power reduction, 4.9% roll throughput yield improvement and 30% defect rate reduction through application of AI algorithm, which significantly contributes to product quality and optimization.