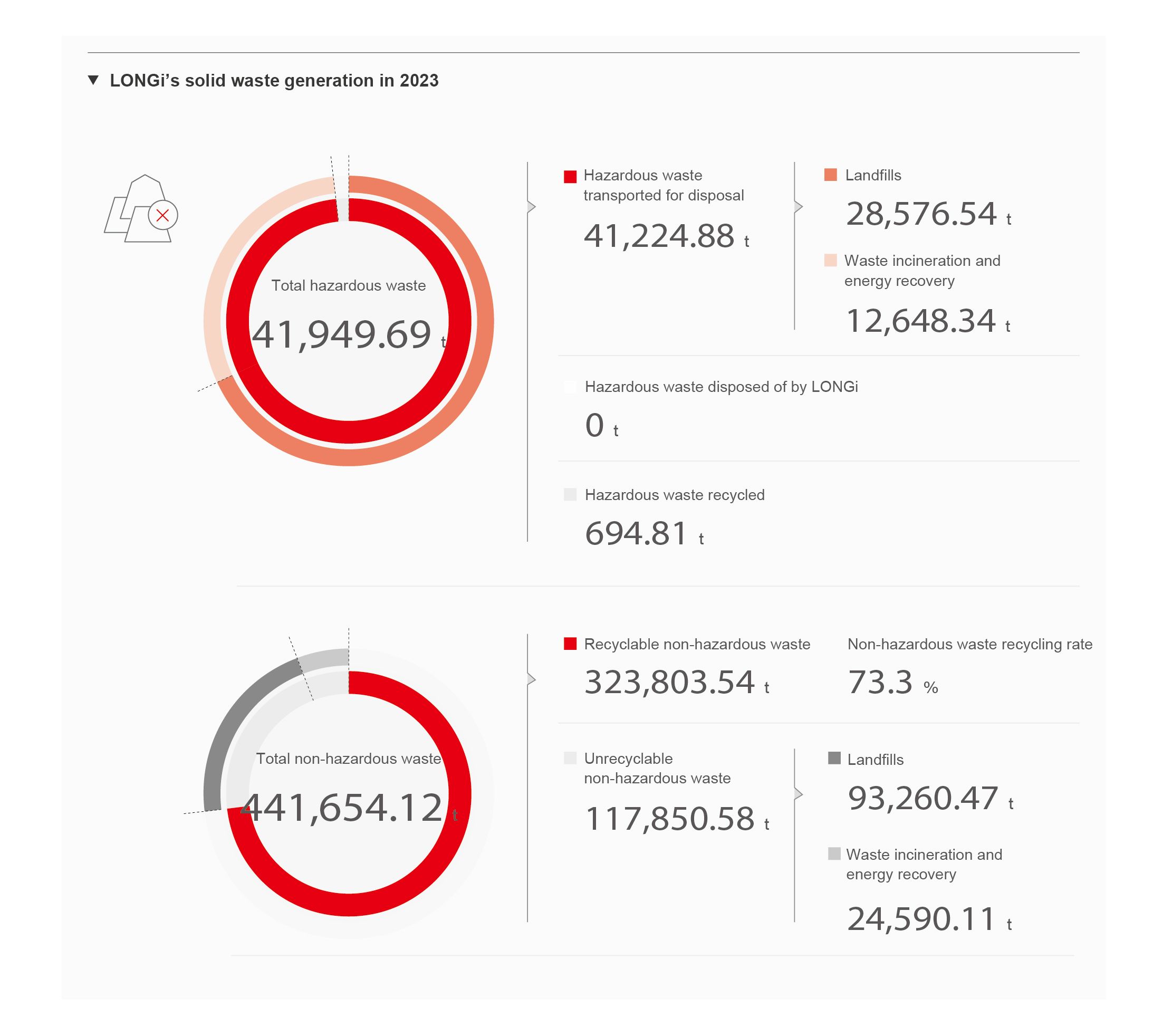

Wastewater management

LONGi’s industrial wastewater is mostly generated during processes such as silicon rod slicing, cell production, preparation of concentrated water, and ground cleaning. To mitigate water pressure and environmental impact, we have been improving the capacity of wastewater treatment to ensure that wastewater meets the discharge requirements before entering the municipal pipe network. In 2023, we adopted measures such as coal mine drainage recycling and evaporation and filtration wastewater recycling, which further reduced production wastewater discharge.

Case| LONGi implemented the wastewater treatment capacity improvement project

In 2023, several production bases of LONGi carried out wastewater discharge reduction projects. Shaanxi LONGi solved the problems of chloride ion erosion in the original ultrafiltration (UF) system, second-stage membrane fouling in reclaimed water reverse osmosis (RO), and the low position of the drainage pipe of the reclaimed water and concentrated water tanks. In doing so, Shaanxi LONGi ensured a more environmentally friendly and stable reclaimed water treatment system and reduced tap water consumption by 1.26 m3/10,000 wafers. In response to the increase in wastewater pollutants caused by greater production capacity, some of LONGi’s production bases in Yunnan, Ningxia, and Xi’an have upgraded the wastewater treatment system and installed the Fenton treatment system, effectively controlling the discharge of chemical oxygen demand (COD) in wastewater.

LONGi’s wastewater discharge in 2023